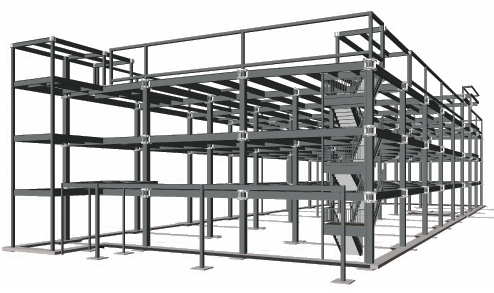

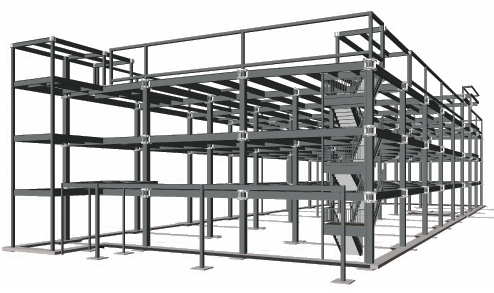

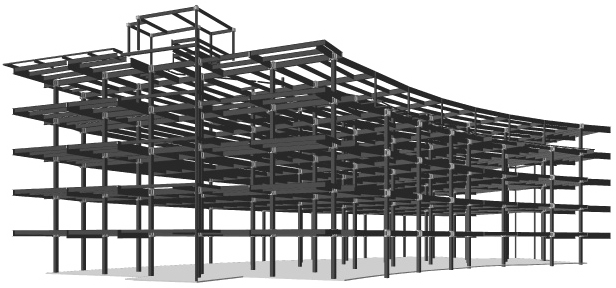

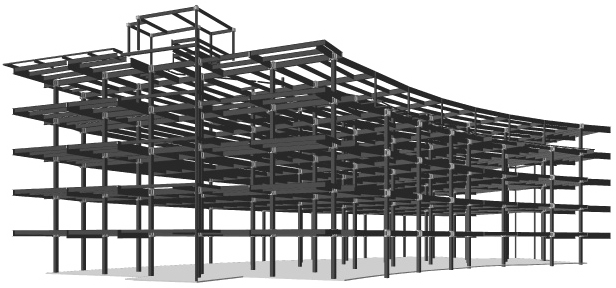

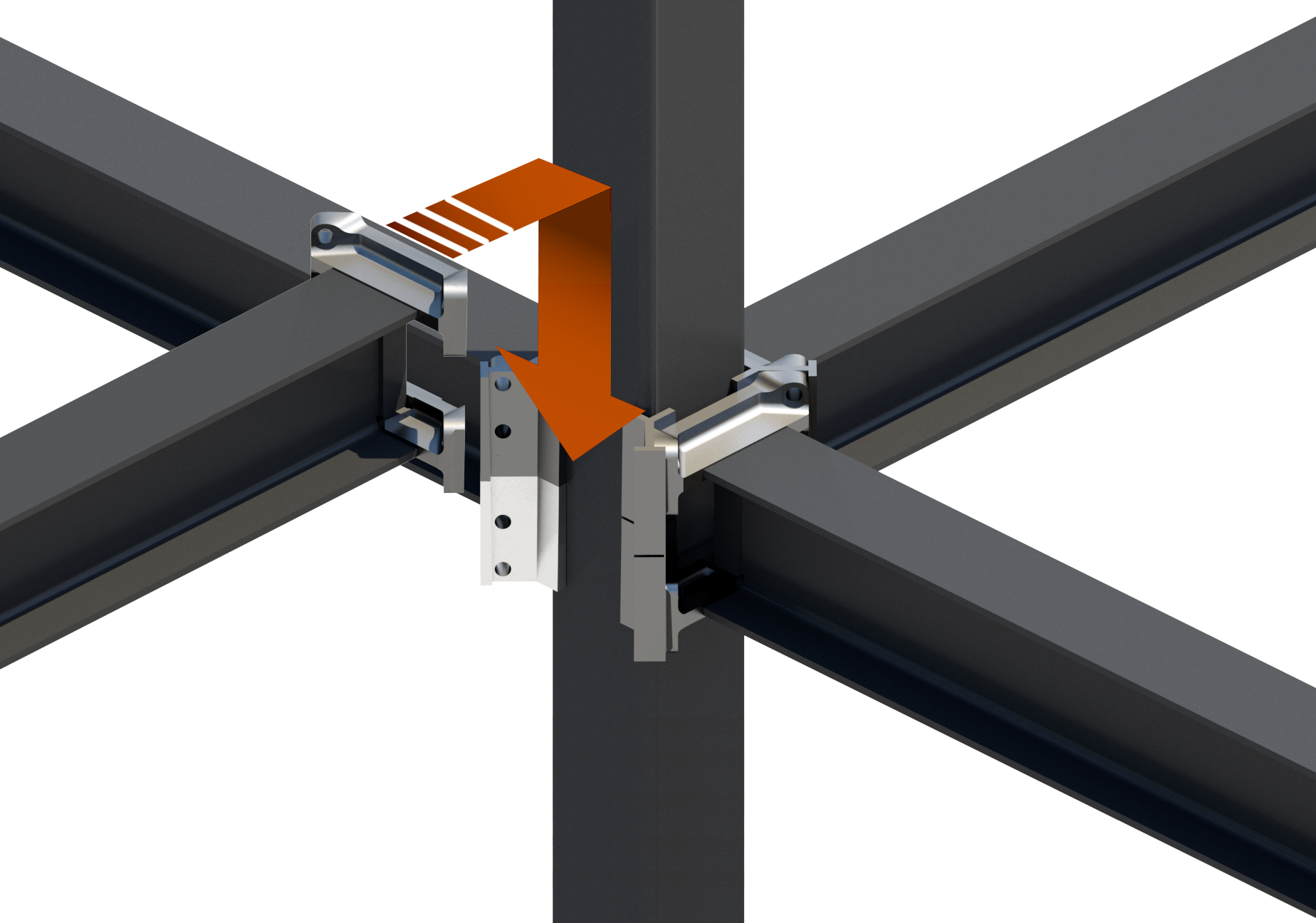

ConXtech structures are designed with tapered, “lower & locking” steel connections that enable safe and rapid assembly. Each ConX System has a standard connection, column size and range of beam spans that form a kit of parts. The building parameters dictate the use of each system. Below are the three ConX Systems and their general parameters. Each is a standalone system and can be used throughout the primary frame as a SMF (Special Moment Frame) or FMC (Flexible Moment Connection) and supplemented with ConX Gravity Connections or other Lateral Force Resisting Systems for a hybrid approach.

Assembly Rate

Design Parameters

Markets

Assembly Rate

Design Parameters

Markets

Assembly Rate

Design Parameters

Markets

* Allowable beam depth can be greater than or less than this range, dependent upon structural performance criteria.

** Allowable spans may vary from those shown above, dependent on beam tributary area and floor loading.

ConX® Gravity Connections

ConX Gravity Connections are “lower & locking,” bolted connections used for secondary and joist beams, and can be incorporated into all three ConX Systems. ConX Gravity Connections have the same self-aligning, gravity-stabilized features of ConXtech’s moment connections — enabling fast, safe assembly without field welding.

ConX Gravity Connection, Beam to Column

ConX Gravity Connection, Beam to Beam

ConX® Systems

ConXtech’s mass-customizable structural steel Flexible Modular Building System is made up of standard connections and used to organize and support other modular systems or assemblies. This not only applies in the built environment, but also in the digital environment during design, using standardized modular connections and interfaces – creating a “System of Systems” which enables simple integration of other modular parts.

Scope Provided:

- ConX Beam Assemblies

- ConX Column Assemblies

- ConX Collar Assemblies

- ConX Standard Egress Stairs

- ConX Elevator Support Steel

- ConX Edge Closure

- MEP Integration

- Exterior Skin System Integration

- Decking