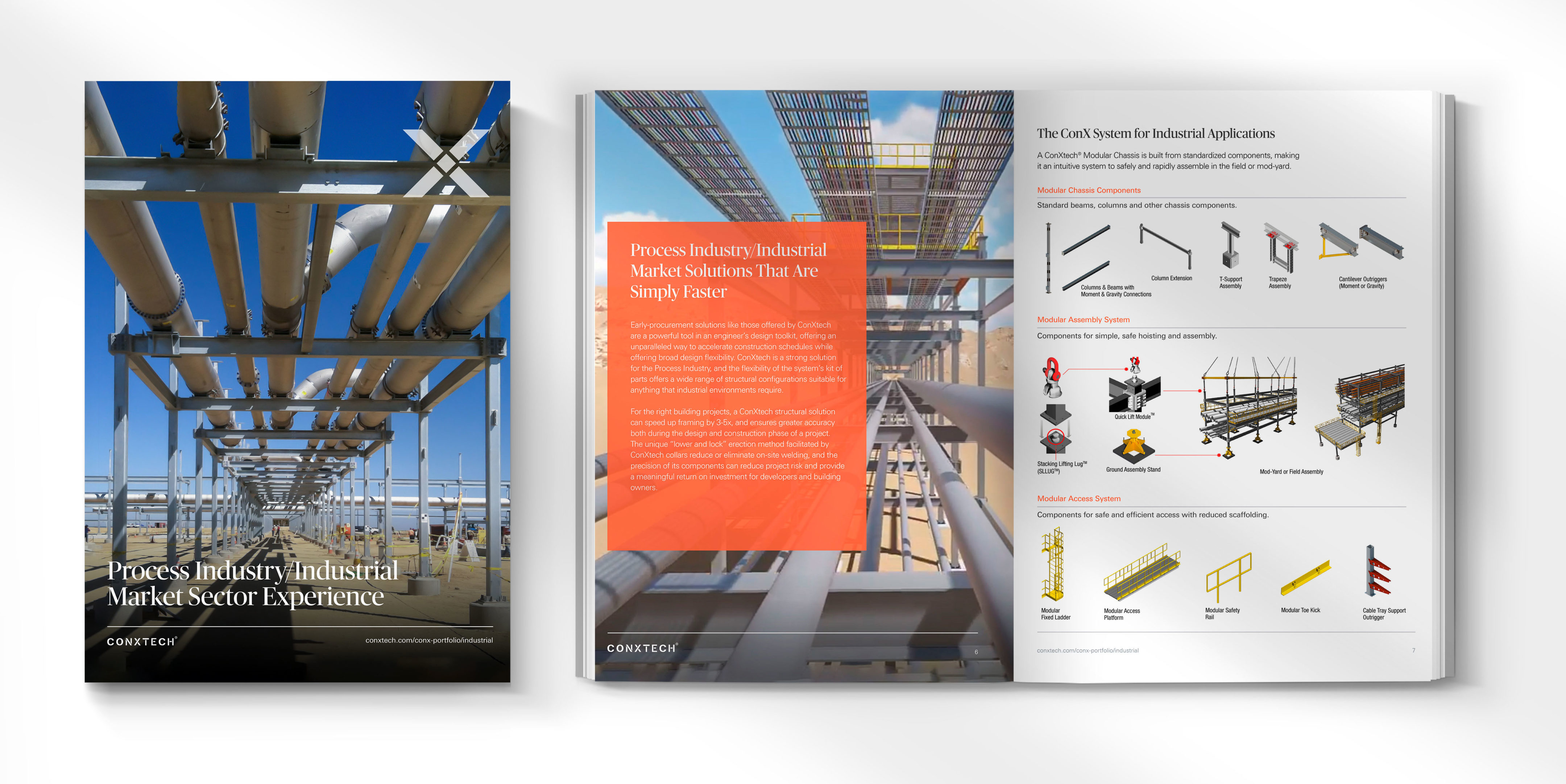

Process Industry/Industrial Market Sector Experience

For nearly two decades, ConXtech has teamed with high-profile Industrial clients to design and deliver innovative structures that improve safety and predictability while reducing Total Installed Costs (TIC). As a result, ConXtech is an ideal structural solution for Industrial applications, offering accelerated installation schedules, simplified layout, and future programmability.

Click the View Now button to review Conxtech’s Industrial Experience PDF document!

ConX® for Industrial Structures

The ConX® System is an ideal structural solution for pipe rack, processing and other industrial applications. With its speedy, safe assembly and inherently brace-free design, ConX significantly simplifies not only the structure, but pipe and equipment installation.

Contact info@conxtech.com to learn more.

Safety and speed with a modular solution

The structurally robust ConX® System is an ideal solution for the efficient design, fabrication and construction of pipe rack and processing structures. ConXtech and its growing network of certified fabricators leverage standardized connectors and employ automated manufacturing technologies to deliver modular and typically brace-free structures. This technology enabled approach accelerates design through delivery allowing industrial facilities to come on-line months or years earlier vs. more conventional structural options.

ConXtech’s innovative connectors are manufactured and factory welded onto wide flange beams and square columns (HSS or box), resulting in pre-fabricated assemblies. This Full-Scale Erector Set™ comprised of ConX assemblies is easily transported and safely and rapidly ‘lowered and locked™’ together in the mod-yard (as modules) or field (stick-built). ConX is intuitive to assemble and ideal where there is a shortage of qualified labor.

ConXtech has also developed foundation systems, layout tools and templates which ensure unprecedented accuracy and predictability in the field.

Benefits of ConX compared to conventional delivery

- Safer to assemble: ConX Lower and Locking™ connections and integrated self-aligning stacking/lifting lug improve safety and require fewer workers and fewer man hours.

- Faster to erect: Accelerated schedule (2 – 5X faster) lowers overall risk and brings rapid ROI. Template based and systemized footing and foundation options also accelerate schedule.

- Brace free structure: Simplifies pipe layout and routing, and often reduces rack levels required. Also, site maintenance is easier without a lot of bracing in the way of access to do repairs.

- Modular factory fabricated frame assemblies: Can be stick built or assembled into modules, transported, safely assembled or disassembled and then reconfigured/re-used.

- No field welding: Bolted bi-axial moment frame structure requires minimal if any field welding. The modular connection points and holes built into beams and columns reduce field rework costs.

- Fewer man hours: Significantly less on-site labor required vs. conventionally built pipe rack.

- Plug & play modules: Simplify maintenance and allow for configurability and future modifications.

- Green: Optimization of materials and redundantly distributed robust connections often result in lighter and greener structures.

Sample Projects

Most of ConXtech’s industrial work is confidential. However, the projects below give a sense of the schedule savings and efficiencies possible with the ConX System.

Modular Pipe Rack Demo

Watch a 45-ton ConX Pipe Rack Module be assembled in 6:17! ConX Pipe Racks are designed as a modular kit-of-parts for efficient design, safe and rapid assembly, and reconfigurability.

The ConX Modular Pipe Rack demo, erected in Alberta, Canada, went up in just six hours with only six iron workers, several of whom had never before assembled a ConX structure.

Aera Pipe Rack

- 1,411 assemblies, 567 tons, 2,701 feet of rack

- ConX Shop Man Hours Per Ton: 7.2 (conventional 15 to 50)

- ConX Field Man Hours Per Ton: 4.23 (conventional 15 to 25+)

- ConX Detailing and Design: 2 weeks with less than 20 shop drawings (conventional = many months / iterations / hundreds of drawings)

- Owner credits ConX for taking 9 months off a 3 year schedule