Aera Pipe Rack

Project Details

| Location: | Bakersfield, CA |

|---|---|

| Owner: | Aera Energy LLC |

| GC: | Aera Energy LLC |

| Engineer: | Joshua Moody, S.E. |

| Architect: | Technical Services & Management |

| Steel Fabricator: | ConXtech Manufacturing |

| Steel Erector: | ConXtech Construction |

| ConXtech Scope: | Structural Steel |

Project Narrative

Water Processing Plant on Central California Oil Field

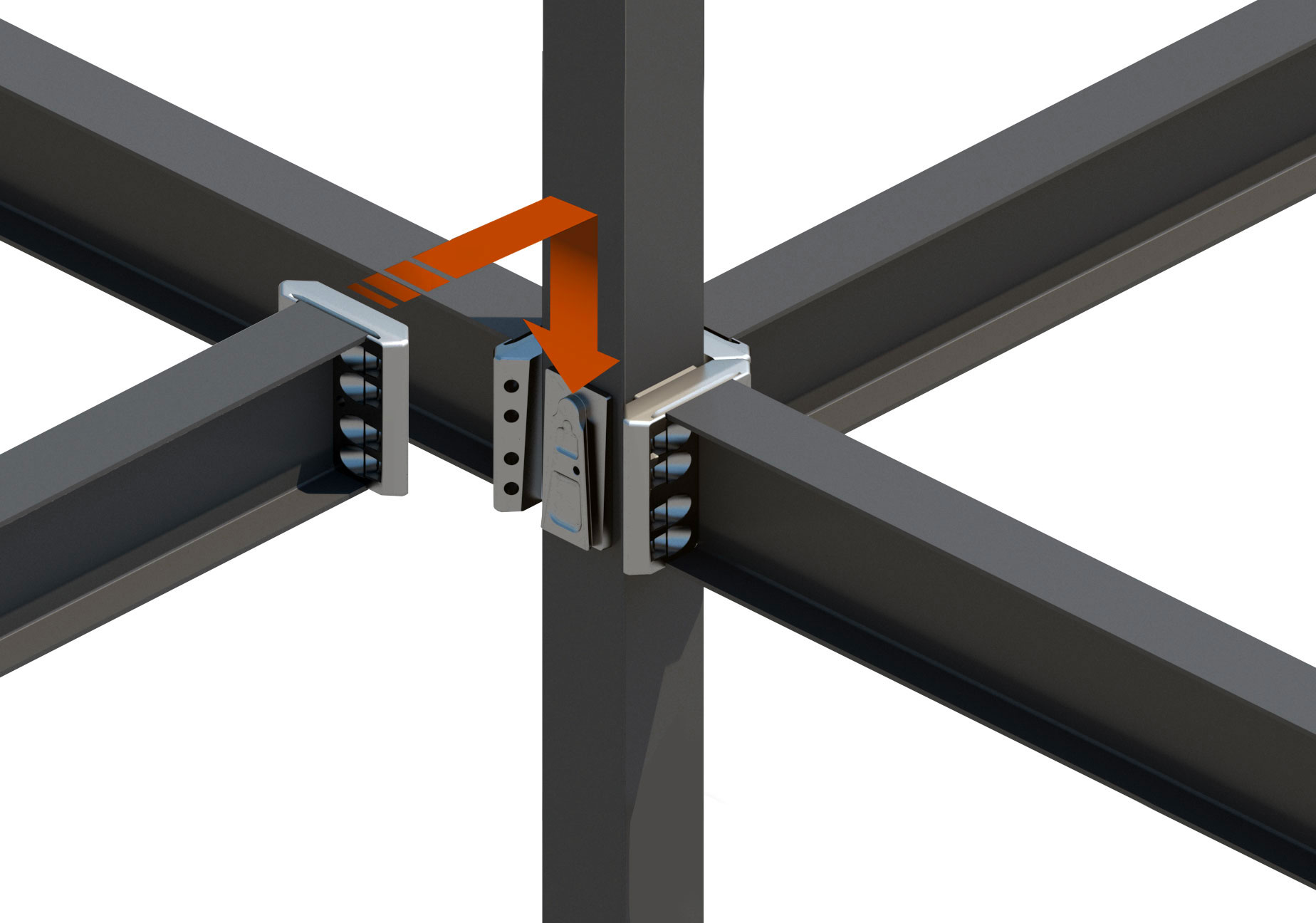

ConXtech has an ideal solution for Pipe Rack and Processing structures. Safe and rapid to erect, ConXtech’s modular approach brings efficiencies in cost and materials. The brace free and structurally robust ConXR System made it possible to design for the worst case scenario, and then fabricate and erect the structure before the piping layout/design was finalized. Other modular pipe rack components designed and provided by ConXtech will be integrated into the structure as the project progresses.

ConX Solutions

The Owner’s Senior Project Manager estimates that utilizing the ConX System will save their company 1 year off of an otherwise 4 year schedule. Starting production in this oil field one year earlier makes the ROI measurable and significant.

Presentation at 2011 LCI Conference

Watch this video recording of a presentation from the 13th Annual Lean Construction Institute Congress 2011, in which an Aera project engineer explains (at 21:40 min mark) how using the prefabricated ConX System brought significant time and monetary savings to the owner.