Confidential Life Sciences Pharmaceutical Manufacturing Facility

Project Details

| Location: | Rahway, NJ |

|---|---|

| Region: | North East |

| Owner: | Confidential |

| GC: | Integrated Project Services |

| Engineer: | Mainstay Engineering Group |

| Architect: | Integrated Project Services |

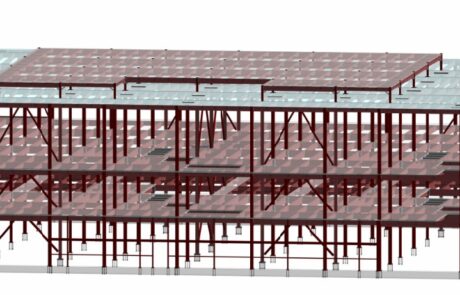

| ConXtech Scope: | Supply and Installation of Structural Steel, Edge Closure, Elevator Steel, Prefab Stairs, and Metal Decking |

Project Narrative

Integrated Project Services (IPS) invited ConXtech to be a part of this life sciences manufacturing campus. During the early stages of conceptual design, IPS suggested to the owner and building end-user that they attend a ConXtech presentation to understand the value that our steel solution brings to the construction process. ConXtech’s proposed solution aligns with the owner’s goals of reducing onsite labor, improving field safety, and accelerating the overall project schedule. This 165,000 sq. ft. pharmaceutical manufacturing facility expands an existing life sciences campus that ConXtech rapidly deployed to meet the demands of the medical market. ConXtech provided a cost-competitive solution, met all building performance criteria, reduced significant man-hours off the jobsite and into a controlled shop environment, and shortened the delivery timeline for the combined structural steel and metal decking package from approximately 80-85 days to 26 days.

ConX Solutions

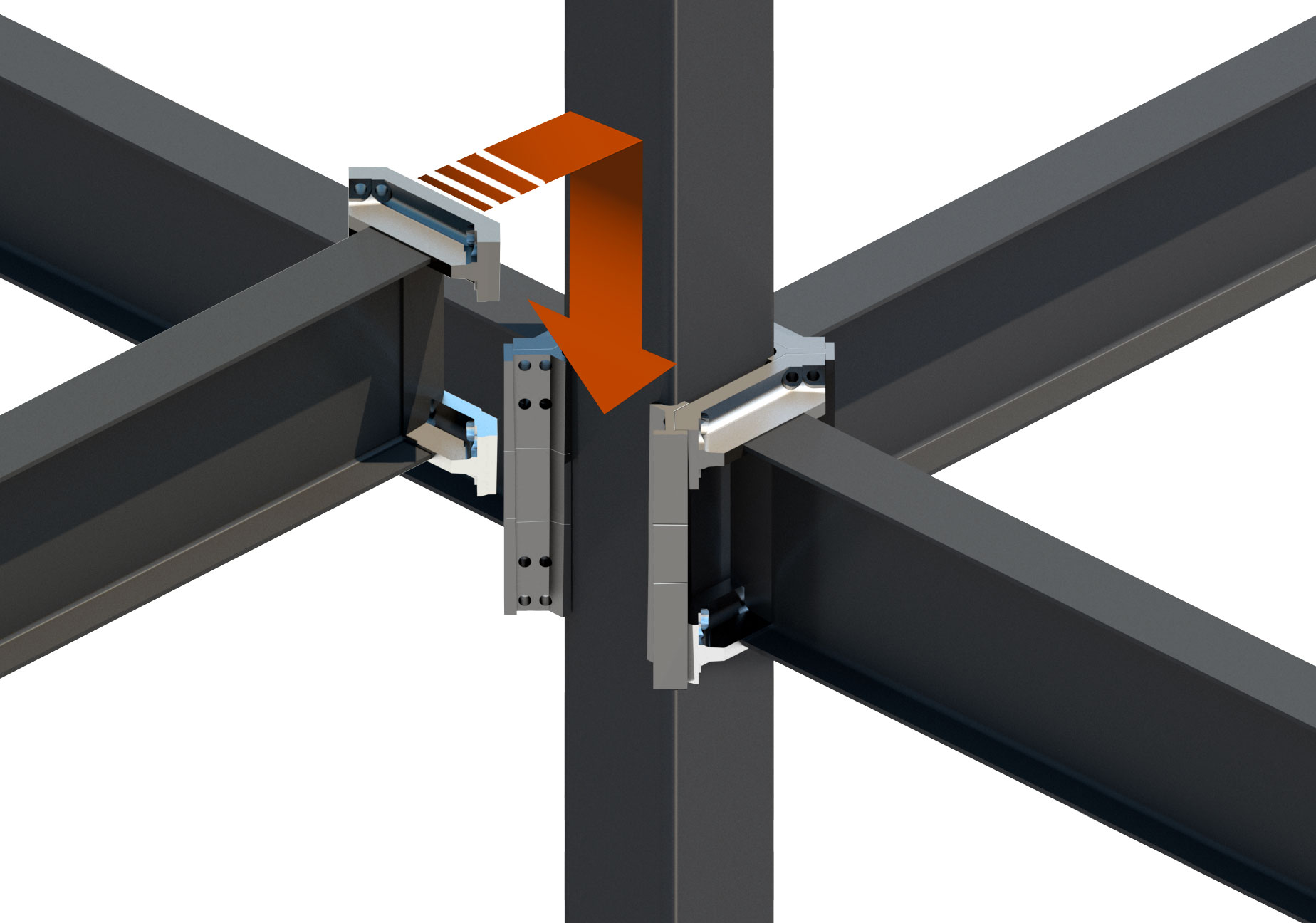

Employing non-seismic braced frames as the Lateral Force Resisting System (LFRS), ConXtech integrated ConXtech XL400 collars as Flexible Moment Connections (FMCs). This ConXtech FMC system serves a dual purpose: first, providing essential stability and alignment during frame erection; and second, transitioning to become part of the gravity load system in the final structure, thus not participating in the LFRS. ConXtech’s FMC solution reflects the latest evolution in ConXtech’s design approach and can be paired with any LFRS. ConXtech proposed this approach for subject program as it provided the most efficient frame weight and cost while still allowing for safer steel erection and a field assembly rate that cannot be matched by any other competing structural system.